Related Products

Unlocking the Secrets of Embossing/Crimping Assemblies: Common Questions Answered

Published:

Jun 20,2025

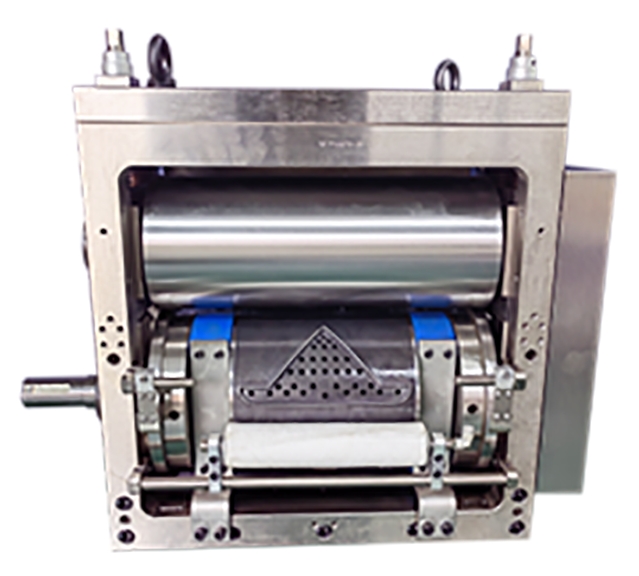

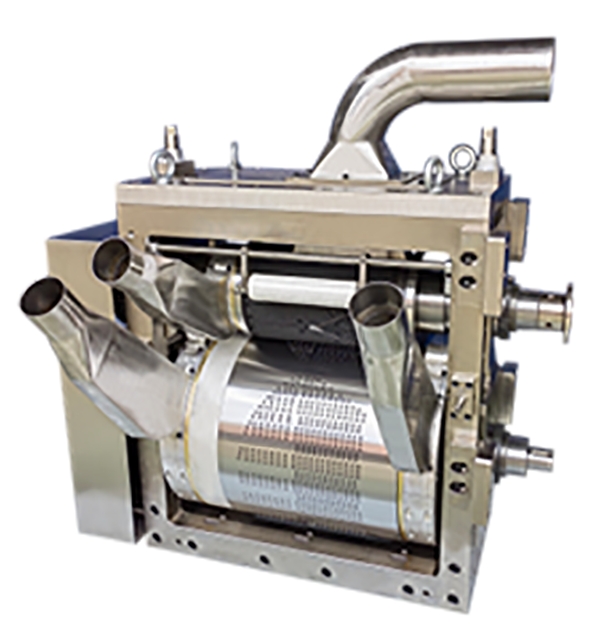

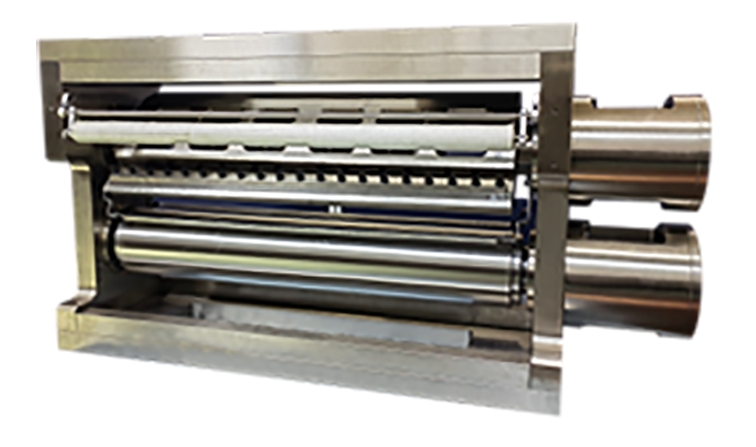

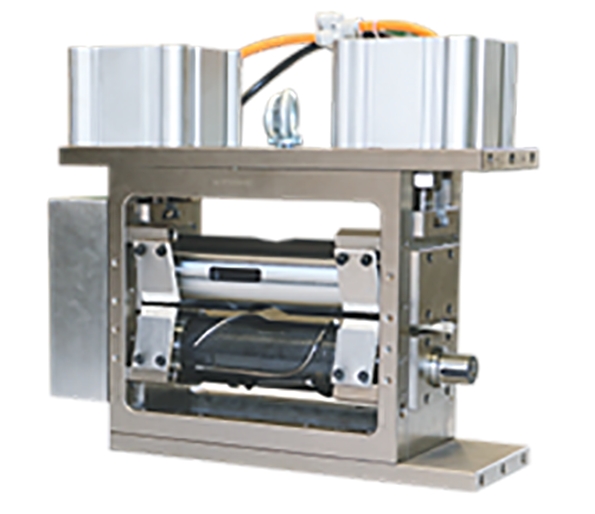

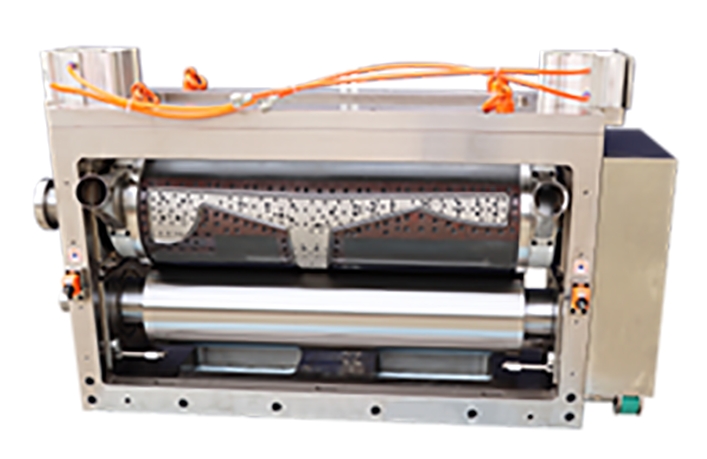

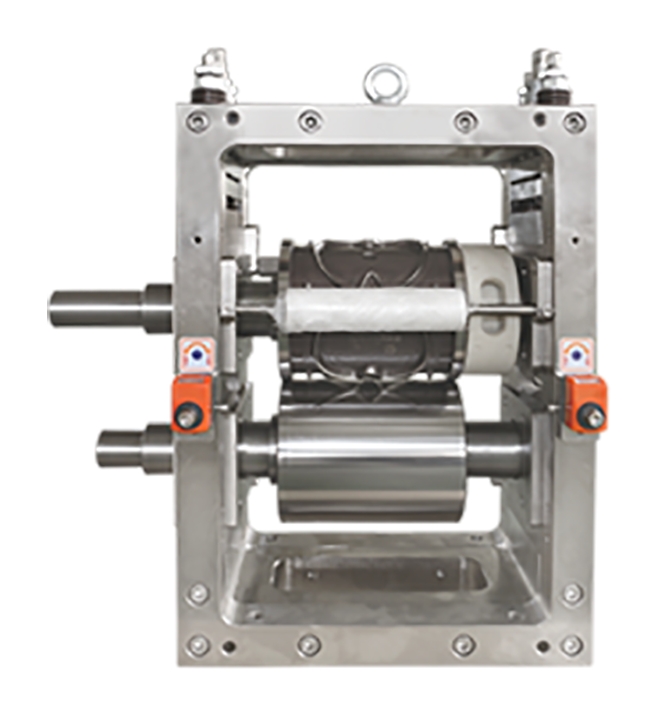

What Are Embossing/Crimping Assemblies?

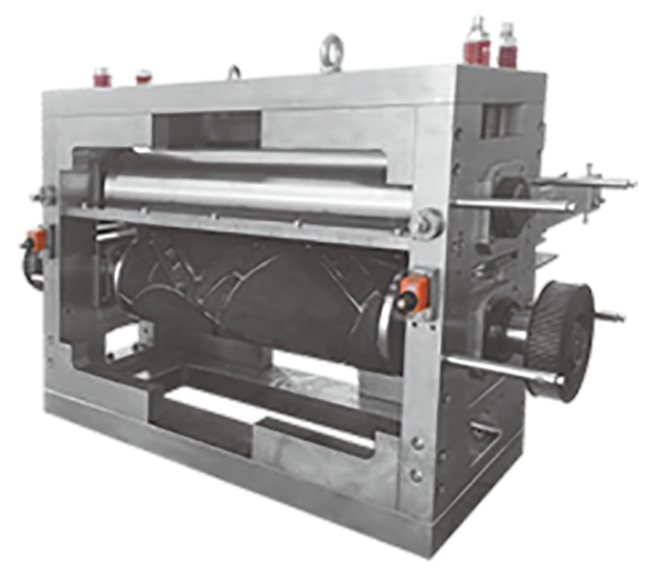

Embossing/Crimping Assemblies are pivotal in various manufacturing processes, especially in the realm of packaging and product assembly. These nifty components help create lasting connections by forming strong bonds between different materials. Whether you're in the automotive, electronics, or even the consumer goods industry, understanding these assemblies can be a game changer!

Why Use Embossing/Crimping Assemblies?

So, why should you bother with these assemblies? Well, for one, they offer a reliable solution to join materials without the hassle of adhesives or welding. Plus, they save time and reduce costs, which is always a win-win, right? The crimping process, in particular, creates a mechanical interlock that’s tough as nails!

Common Questions About Embossing/Crimping Assemblies

1. What materials can be used with these assemblies?

Great question! You can use a variety of materials, including metals, plastics, and even some composites, depending on the application. Just make sure to choose the right assembly for the job to ensure optimal performance.

2. How do I choose the right assembly?

Ah, the million-dollar question! Selecting the right embossing or crimping assembly boils down to a few key factors: the type of materials being joined, the required strength of the connection, and the specific application. It's all about matching the assembly to your unique needs!

3. Can these assemblies be reused?

In most cases, no. Once you’ve crimped or embossed a connection, it’s designed for a one-time use. Trying to reuse them could lead to weak connections or even failure. Yikes!

4. What are the benefits of using these assemblies?

There are plenty! They’re typically quicker to apply than traditional methods, provide excellent durability, and are generally more cost-effective over time. Plus, they minimize the need for additional materials, which is always a plus for the environment!

Tips for Working with Embossing/Crimping Assemblies

Now that you’ve got a handle on the basics, here are some tips to keep in mind:

- Always ensure that your materials are clean and free of contaminants.

- Follow the manufacturer’s recommendations for tool settings to achieve the best results.

- Don’t rush the process! Take your time to ensure a secure connection.

- Regularly inspect your assemblies for wear and tear, especially in high-stress applications.

Conclusion

In summary, Embossing/Crimping Assemblies are essential tools in many industries, and understanding their functionality can significantly impact your production quality. With the right knowledge, you can tackle any assembly challenge that comes your way. So get out there, and start embossing or crimping your way to success!

keywords

2025

06-16

Proway Core Punching Die-Cutting Assembly Achieves 900 Pieces/Minute in Customer Acceptance Test

2024

05-25

The 30th International Life Paper Annual Conference of Nanjing International Expo Center in 2023

2025

07-04

Innovations in Adult Diaper Cutting Technology: What You Need to Know

2025

06-27

Innovations in Adult Diaper Cutting Assembly: A Practical Approach

Social Media

Contact

Add: No. 6 Gaoyuan Industrial Zone, Meilie District, Sanming City, Fujian Province, China

Tel: +86 598 8365699

Email: sales@cnpnv.com / pnv@cnpnv.com

All Rights Reserved © 2024 Sanming PNV Machinery Co.,Ltd.

- Inquiry