Related Products

Innovations in Adult Diaper Cutting Assembly: A Practical Approach

Published:

Jun 27,2025

Introduction

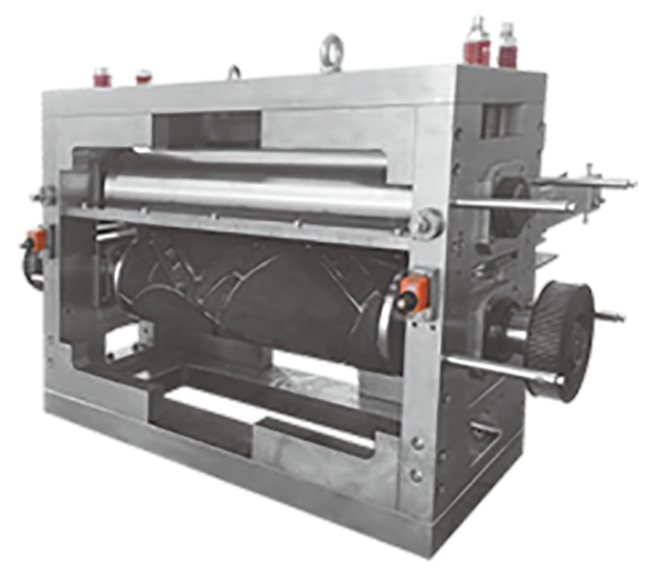

In the world of hygiene products, adult diapers play a crucial role. As the demand continues to rise, manufacturers are constantly seeking ways to improve their production processes. One of the key components in creating these products is the adult diaper cutting assembly—a pivotal piece of machinery that ensures efficiency and quality. Let’s dive into this fascinating subject!

The Importance of Cutting Assemblies

First off, let’s get one thing straight: the cutting assembly is not just any old machine. It’s the heart of the production line! Without it, manufacturing would be a chaotic mess, leading to wasted materials and time. The adult diaper cutting assembly streamlines the entire process, making it more efficient and cost-effective.

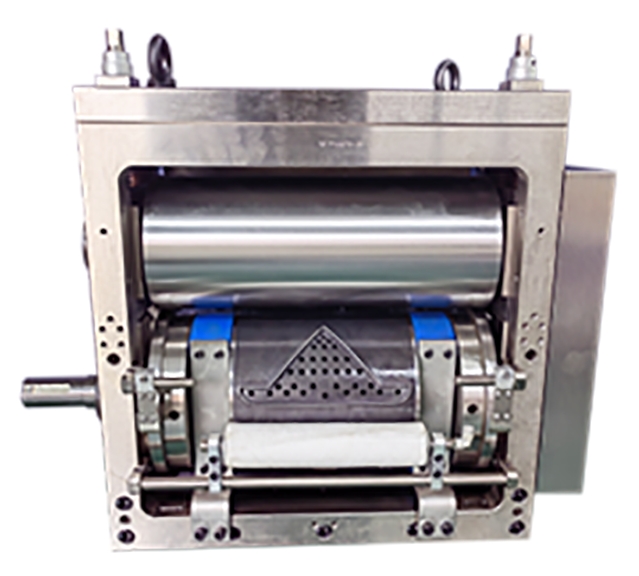

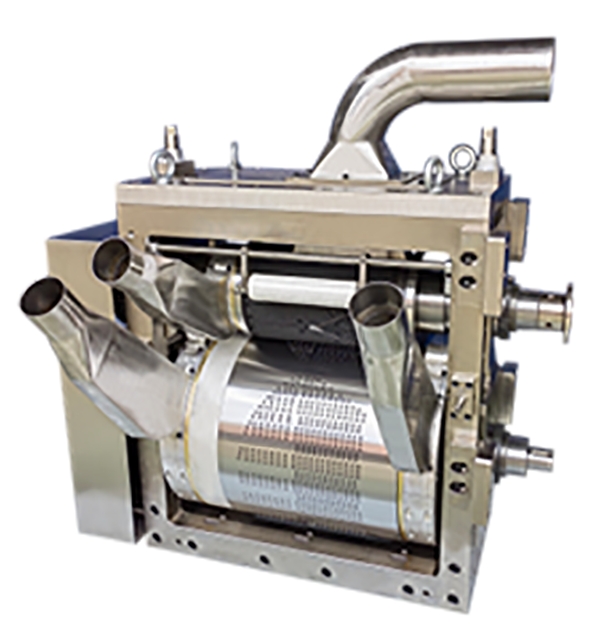

How Does It Work?

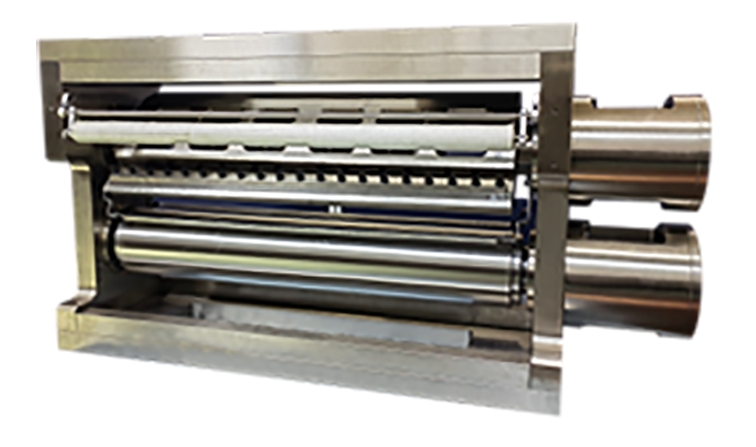

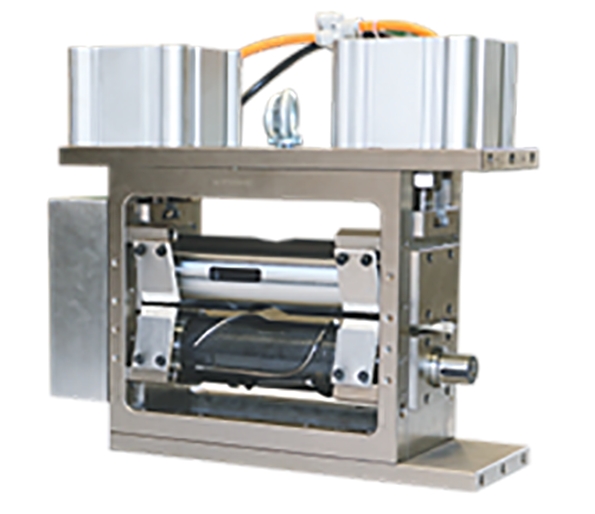

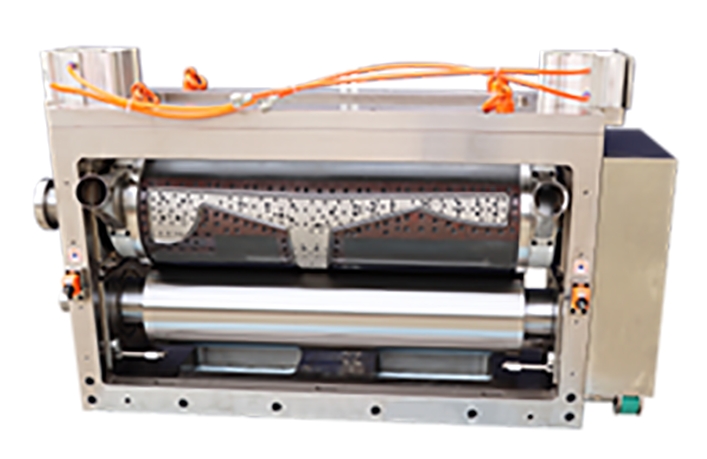

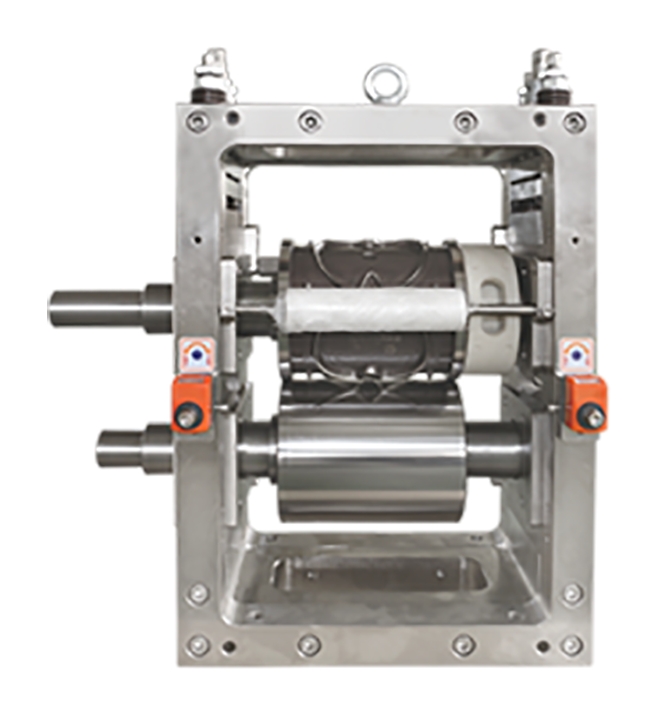

Now, hold onto your hats! The mechanics behind this assembly are quite impressive. It takes raw materials, like non-woven fabrics and absorbent cores, and slices them into perfectly sized pieces. Think of it like a chef dicing vegetables—precision is key! This not only ensures uniformity but also reduces the chances of defects, ultimately leading to a higher-quality product.

Components of a Cutting Assembly

So, what makes up the adult diaper cutting assembly? Here are a few critical components:

- Blades: These are the sharpest tools in the shed, designed to make precise cuts.

- Feeding Mechanism: This part ensures that the materials are fed into the cutting area smoothly and consistently.

- Control System: Think of this as the brain of the operation, allowing for adjustments in speed and precision.

Innovations on the Horizon

But wait, there’s more! As technology advances, so do the capabilities of the adult diaper cutting assembly. Manufacturers are now incorporating AI and automation, which significantly enhances speed and accuracy. Imagine a cutting assembly that learns from past cuts to improve future performance—now that's futuristic!

Benefits of Modern Assemblies

With these innovations, the benefits are crystal clear:

- Increased Efficiency: The automation reduces downtime and maximizes output.

- Cost Savings: Less waste means more profit!

- Enhanced Quality: With precise cuts and better materials handling, the end product is top-notch.

Challenges Faced

Of course, no industry is without its hurdles. The adult diaper cutting assembly faces challenges such as maintenance costs and the need for skilled operators to manage advanced technology. However, with proper training and investment, these challenges can be navigated smoothly.

Conclusion

In conclusion, the world of adult diaper production is evolving, and at the center of it all is the adult diaper cutting assembly. As manufacturers embrace new technologies, they’re not just improving their processes; they’re also enhancing the quality of life for countless individuals. So, here’s to innovation and efficiency in a sector that truly matters!

keywords

2025

06-16

Proway Core Punching Die-Cutting Assembly Achieves 900 Pieces/Minute in Customer Acceptance Test

2024

05-25

The 30th International Life Paper Annual Conference of Nanjing International Expo Center in 2023

2025

07-04

Innovations in Adult Diaper Cutting Technology: What You Need to Know

2025

06-27

Innovations in Adult Diaper Cutting Assembly: A Practical Approach

Social Media

Contact

Add: No. 6 Gaoyuan Industrial Zone, Meilie District, Sanming City, Fujian Province, China

Tel: +86 598 8365699

Email: sales@cnpnv.com / pnv@cnpnv.com

All Rights Reserved © 2024 Sanming PNV Machinery Co.,Ltd.

- Inquiry