Related Products

Demystifying Rotary Die Cutting Assemblies: Your FAQs Answered

Published:

May 16,2025

Introduction to Rotary Die Cutting Assemblies

Have you ever wondered how those beautiful, intricate designs on packaging or labels come to life? Well, let me introduce you to the magic of Rotary Die Cutting Assemblies. These nifty tools are essential in the world of manufacturing, especially when it comes to creating precise cuts in various materials. So, buckle up as we dive into some of the most common questions surrounding these assemblies!

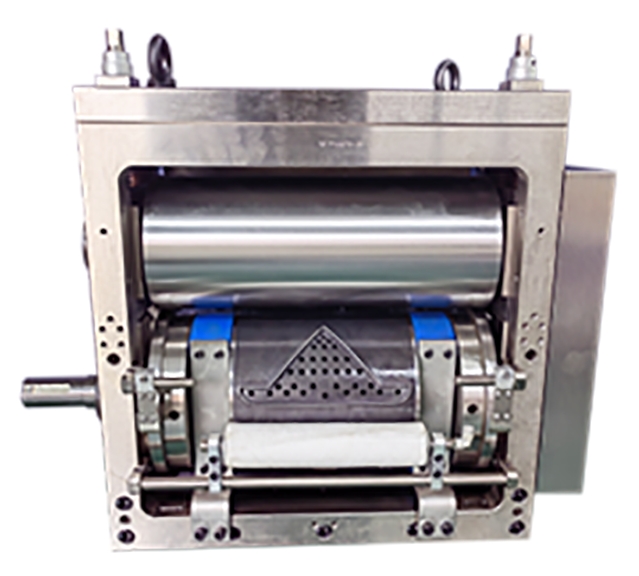

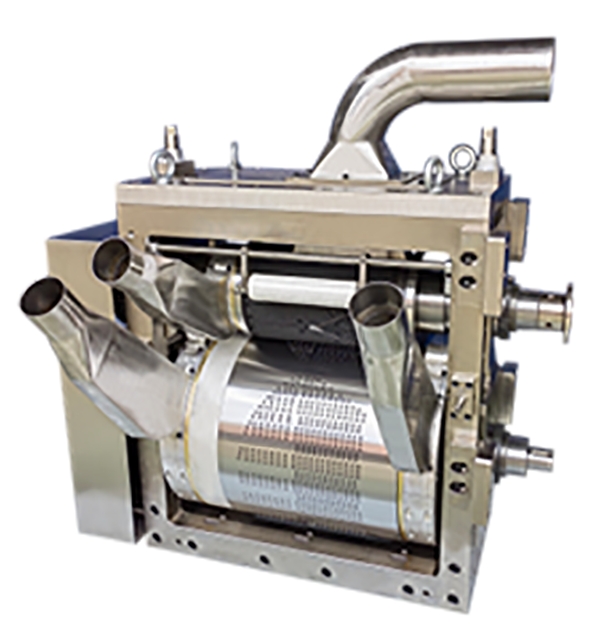

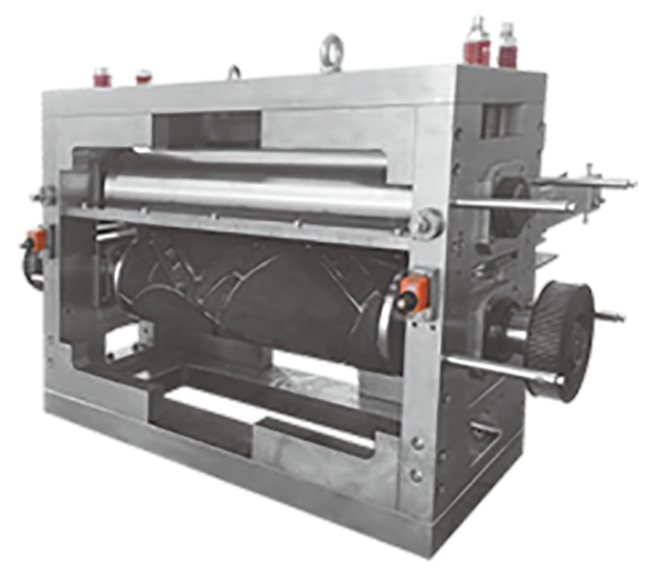

What Exactly Are Rotary Die Cutting Assemblies?

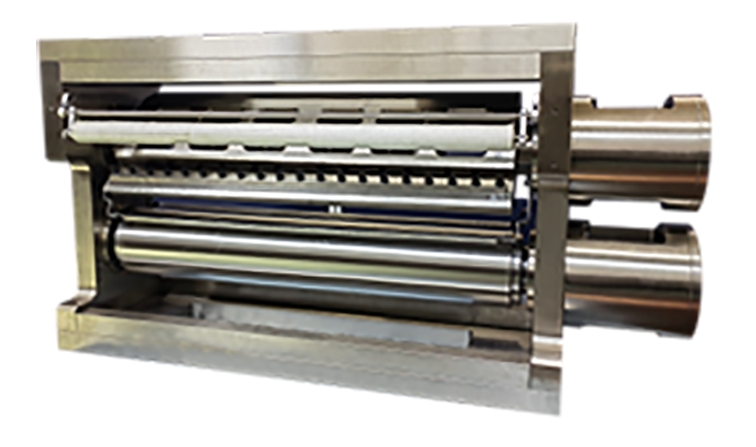

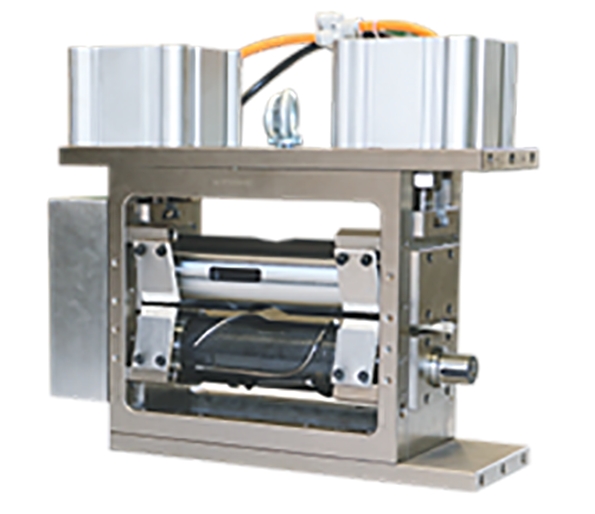

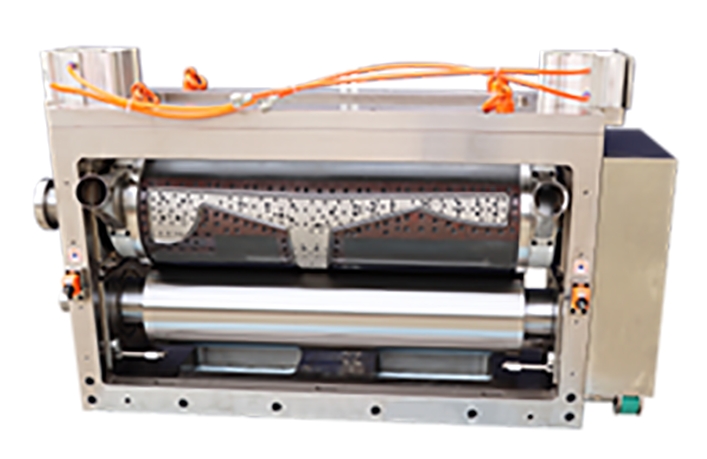

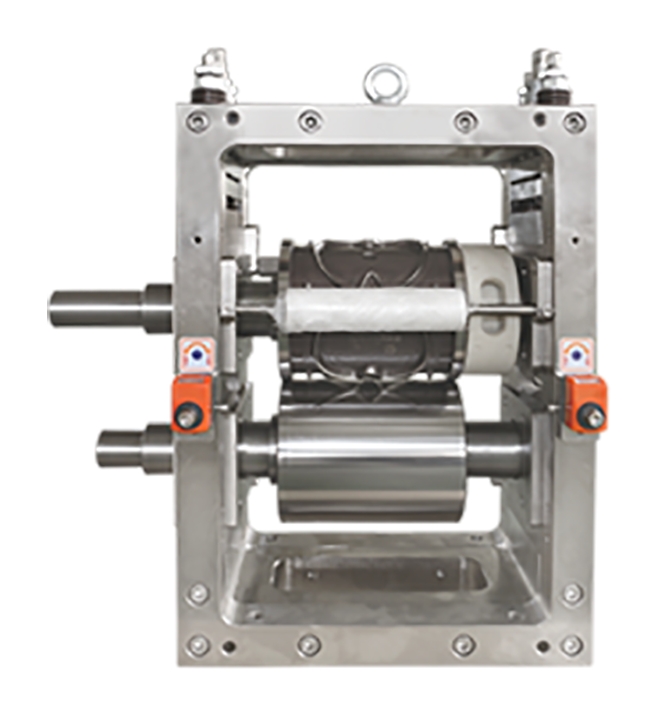

To put it simply, Rotary Die Cutting Assemblies are machines that use rotating dies to cut materials into specific shapes. Think of them as giant cookie cutters on a conveyor belt. They’re widely used in industries like packaging, printing, and label making. With their ability to produce high volumes of cuts quickly and efficiently, they’ve become a staple in the manufacturing toolkit.

How Do They Work?

Alright, let’s break it down. The process begins with a die, which is a custom-made tool that shapes the material into the desired form. The rotary die presses against the material as it moves through the machine, effectively slicing it into the required shape. It’s fast and efficient—ideal for those high-demand production runs.

What Materials Can Be Cut?

You might be asking, “Can I cut anything with these assemblies?” Well, almost! Rotary die cutting can handle a variety of materials, including paper, cardboard, plastics, and even certain metals. It’s versatile, which is why it’s so popular among manufacturers.

Are There Different Types of Rotary Die Cutting Assemblies?

You bet! There are several types of rotary die cutting assemblies, each designed for specific tasks. Some common types include:

- Flatbed Die Cutters: Best for thicker materials.

- Rotary Die Cutters: Perfect for high-speed production runs.

- Laser Die Cutters: Great for intricate designs.

Choosing the right type depends on your specific needs, whether it’s speed, precision, or material type.

What Are the Benefits?

Now, let’s talk perks! Using Rotary Die Cutting Assemblies comes with a multitude of benefits:

- Speed: They can produce large quantities in a short time, which is a win-win.

- Accuracy: The precision is top-notch, reducing waste and errors.

- Cost-Effective: For mass production, they save both time and money.

What’s not to love?

Common Issues and Troubleshooting

Of course, like any machinery, rotary die cutting assemblies can run into issues. Here’s a quick guide to troubleshoot some common problems:

- Inconsistent Cuts: Check the alignment of your die.

- Material Jamming: Ensure the material is loaded correctly.

- Wear and Tear: Regular maintenance is key!

Staying proactive can help you avoid a headache down the line!

Final Thoughts

In summary, Rotary Die Cutting Assemblies are a vital part of the manufacturing process, offering speed, precision, and versatility. Whether you’re in the packaging game or just curious about how things are made, understanding these assemblies can give you a whole new appreciation for the craftsmanship behind the products we use every day. So, next time you see that perfectly cut label or box, you’ll know the magic behind it!

Have More Questions?

If you still have questions or need advice on using rotary die cutting assemblies, don’t hesitate to reach out! There’s always more to learn in this fascinating field.

keywords

2025

06-16

Proway Core Punching Die-Cutting Assembly Achieves 900 Pieces/Minute in Customer Acceptance Test

2024

05-25

The 30th International Life Paper Annual Conference of Nanjing International Expo Center in 2023

2025

07-04

Innovations in Adult Diaper Cutting Technology: What You Need to Know

2025

06-27

Innovations in Adult Diaper Cutting Assembly: A Practical Approach

Social Media

Contact

Add: No. 6 Gaoyuan Industrial Zone, Meilie District, Sanming City, Fujian Province, China

Tel: +86 598 8365699

Email: sales@cnpnv.com / pnv@cnpnv.com

All Rights Reserved © 2024 Sanming PNV Machinery Co.,Ltd.

- Inquiry