Related Products

Unveiling the World of Embossing/Crimping Assemblies: A Game Changer in Fabrication

Published:

Jun 06,2025

Introduction

Hey there! Ever found yourself pondering the intricate processes that make modern manufacturing tick? Well, buckle up, because today we’re diving into the fascinating realm of Embossing/Crimping Assemblies! These nifty little components are the unsung heroes of the manufacturing world, playing a vital role in how products are created and assembled. So, let’s break it down!

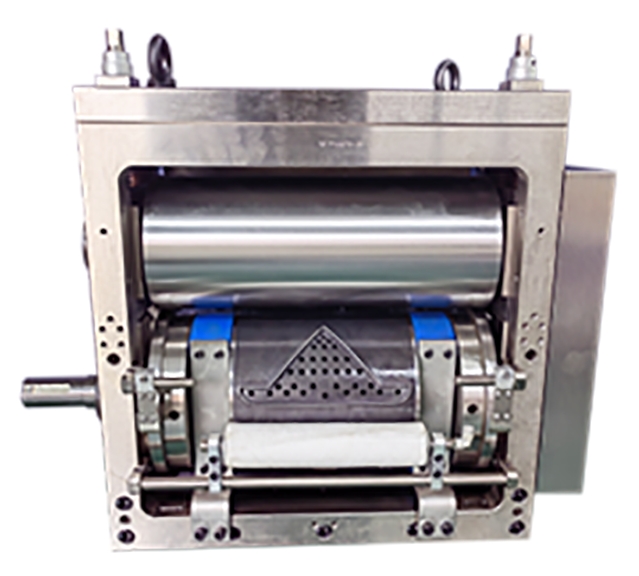

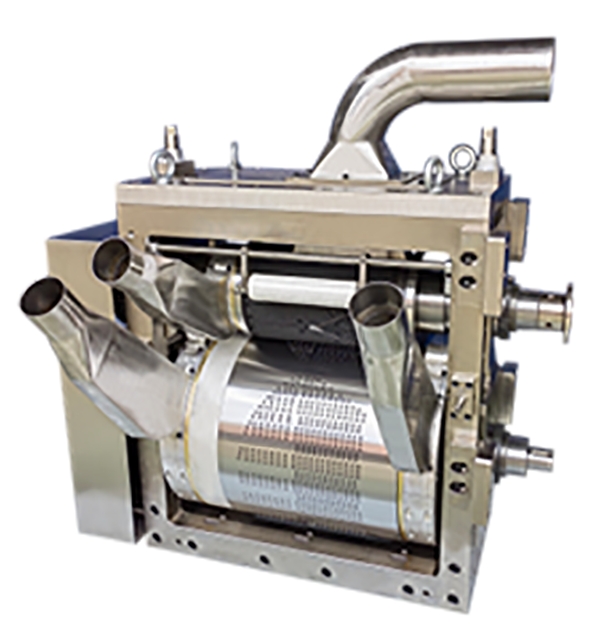

What Are Embossing/Crimping Assemblies?

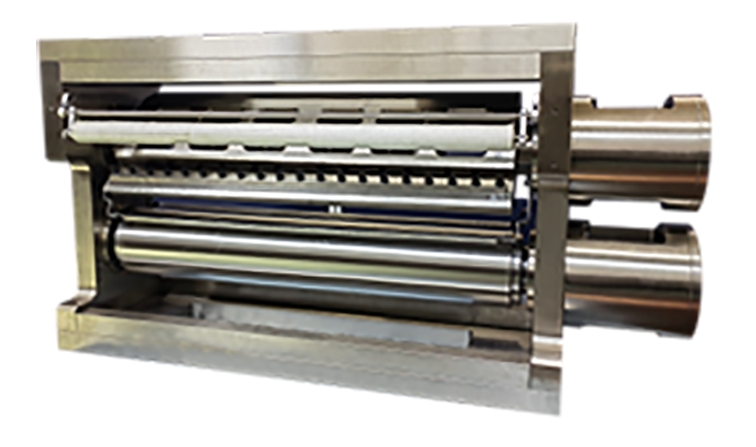

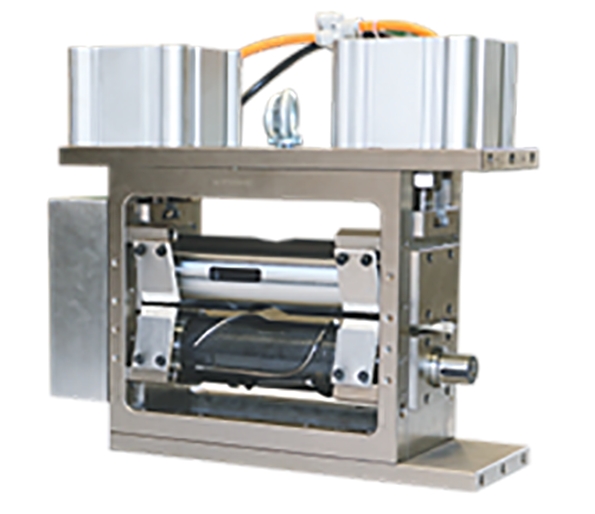

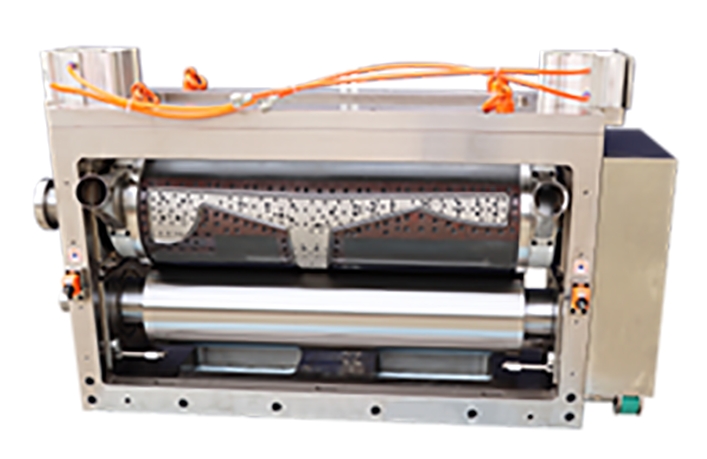

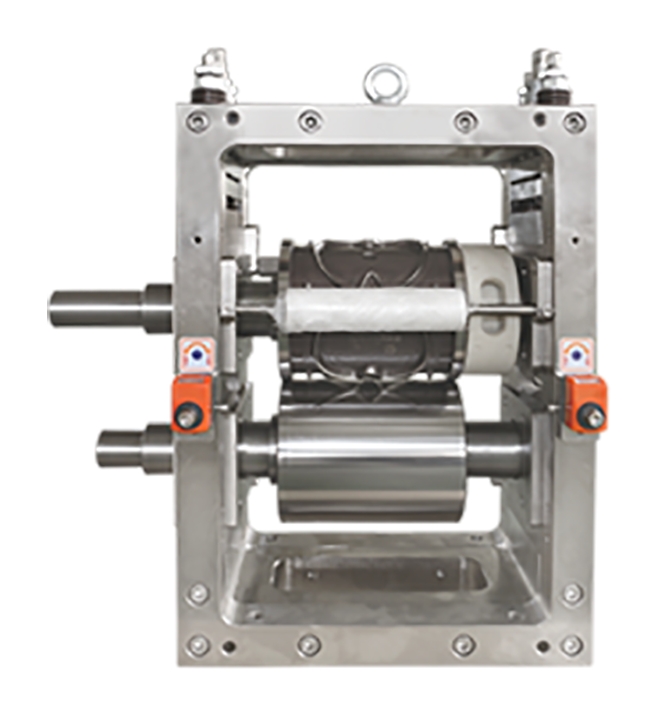

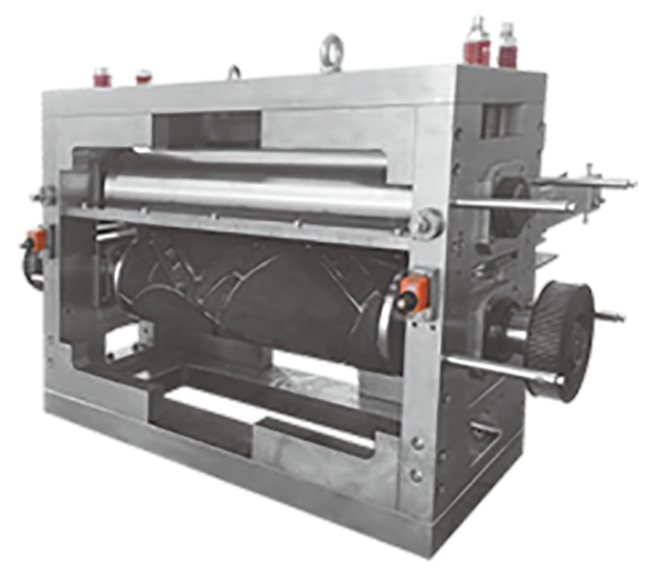

Alright, let’s start at the beginning. Embossing/Crimping Assemblies are specialized tools used in various industries to shape, form, or join materials together. Think of them as the glue that holds everything together, but way cooler! They’re primarily utilized in the production of automotive parts, electronics, and even in crafting those stylish little gadgets we all love.

How Do They Work?

So, how do these assemblies actually work their magic? Well, they utilize a combination of pressure and heat to create a bond between two or more materials. During the crimping process, the assembly compresses the materials, creating a secure connection. On the flip side, embossing involves creating raised designs or patterns on the surface of the material. Pretty nifty, right?

The Benefits of Using Embossing/Crimping Assemblies

Now, you might be wondering, "What’s in it for me?" Here are just a few reasons why using Embossing/Crimping Assemblies is a no-brainer:

- Durability: These assemblies create strong, long-lasting bonds that can withstand various stresses.

- Efficiency: The process is quick and saves time in production, allowing manufacturers to increase output.

- Versatility: They can be used on a wide range of materials, making them suitable for multiple applications.

Real-World Applications

Let’s take a stroll through some real-world applications, shall we? From automotive manufacturing to consumer electronics, Embossing/Crimping Assemblies find their way into countless products. For instance, in the automotive industry, they are used to securely join wires and cables, ensuring that your car runs smoothly. In electronics, they help in assembling circuit boards, making sure everything is connected and functioning as it should.

Challenges and Considerations

But hold your horses! It’s not all sunshine and rainbows. Like any technology, there are challenges to consider. Factors such as the type of materials used, the specific application, and the desired outcome can all impact the effectiveness of Embossing/Crimping Assemblies. Manufacturers need to carefully assess these factors to ensure they are using the right assembly for the job.

The Future of Embossing/Crimping Assemblies

So, what does the future hold? With advancements in technology, we can expect to see even more innovative applications for Embossing/Crimping Assemblies. Imagine a world where these assemblies are integrated with smart technology, improving efficiency even further! The possibilities are endless.

Conclusion

In conclusion, Embossing/Crimping Assemblies are a crucial part of modern manufacturing, bringing together the best of efficiency, durability, and versatility. Whether you’re a manufacturer or just a curious reader, understanding these assemblies opens up a world of possibilities. So next time you see a product, take a moment to appreciate the intricate processes that brought it to life. Happy exploring!

keywords

2025

06-16

Proway Core Punching Die-Cutting Assembly Achieves 900 Pieces/Minute in Customer Acceptance Test

2024

05-25

The 30th International Life Paper Annual Conference of Nanjing International Expo Center in 2023

2025

07-04

Innovations in Adult Diaper Cutting Technology: What You Need to Know

2025

06-27

Innovations in Adult Diaper Cutting Assembly: A Practical Approach

Social Media

Contact

Add: No. 6 Gaoyuan Industrial Zone, Meilie District, Sanming City, Fujian Province, China

Tel: +86 598 8365699

Email: sales@cnpnv.com / pnv@cnpnv.com

All Rights Reserved © 2024 Sanming PNV Machinery Co.,Ltd.

- Inquiry