Related Products

The Future of Embossing/Crimping Assemblies: Trends and Innovations

Published:

May 30,2025

The Future of Embossing/Crimping Assemblies: Trends and Innovations

Hey there! If you've ever wondered what makes certain products stand out—literally and figuratively—you’re in for a treat. Today, we're diving into the fascinating world of Embossing/Crimping Assemblies. These nifty little components are at the forefront of innovation in various industries, and they’re more than just a pretty face!

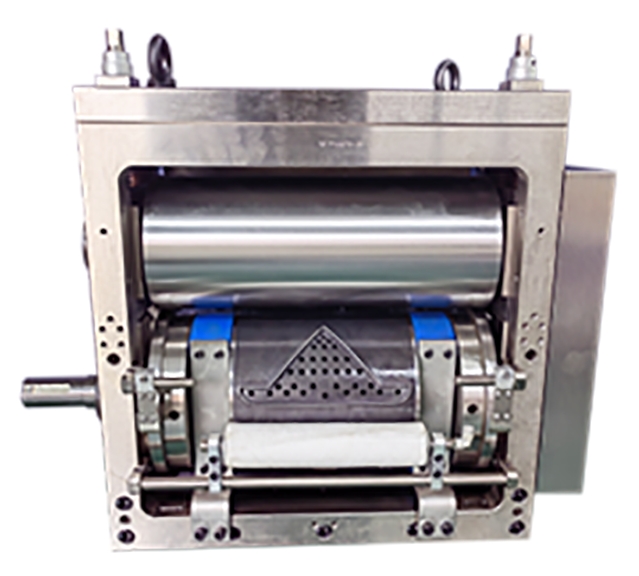

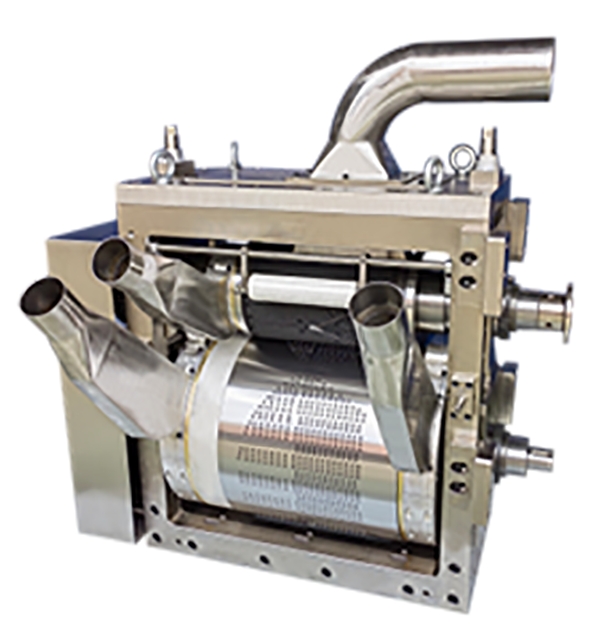

What Are Embossing/Crimping Assemblies?

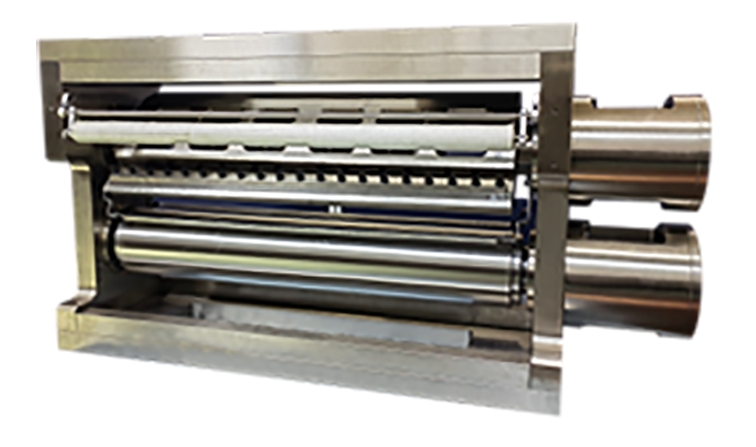

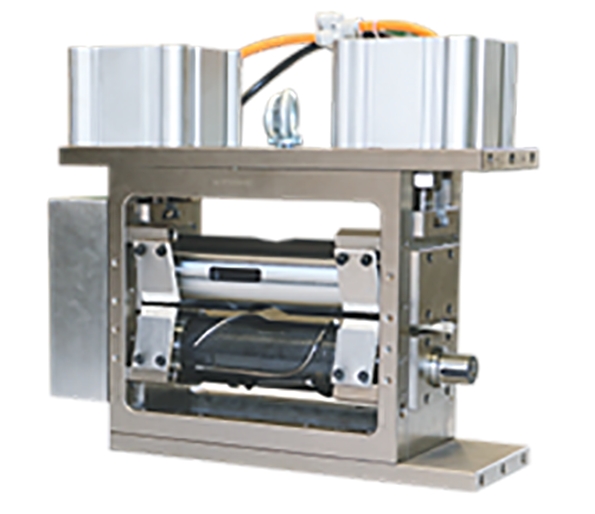

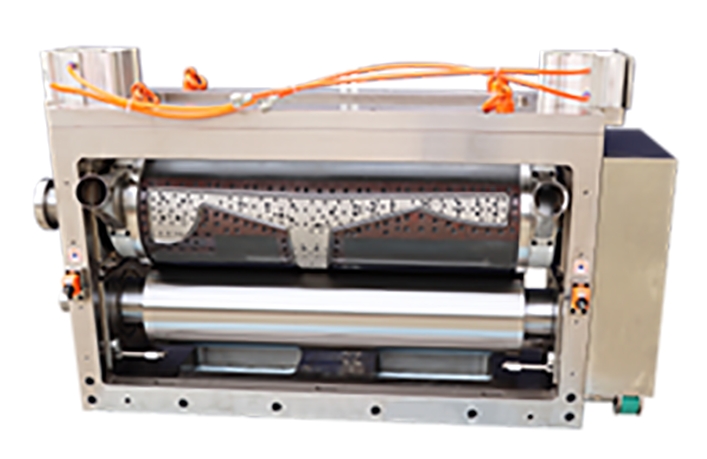

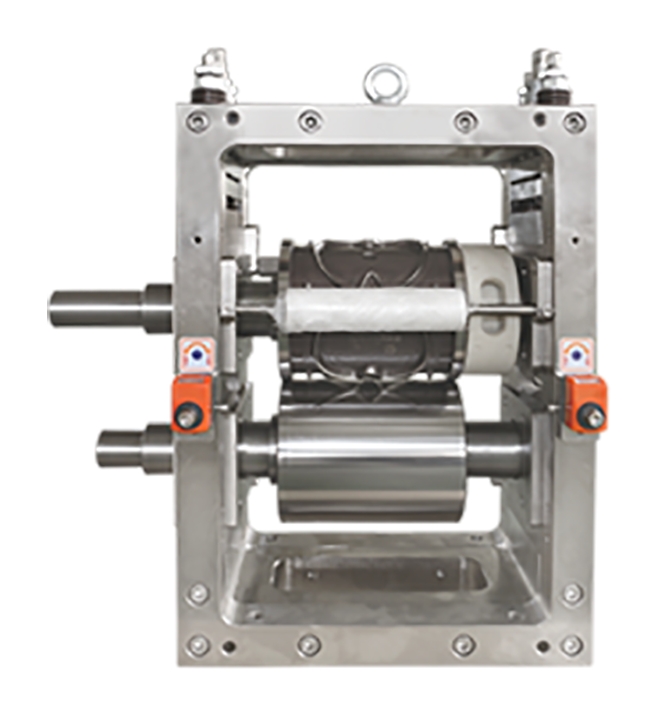

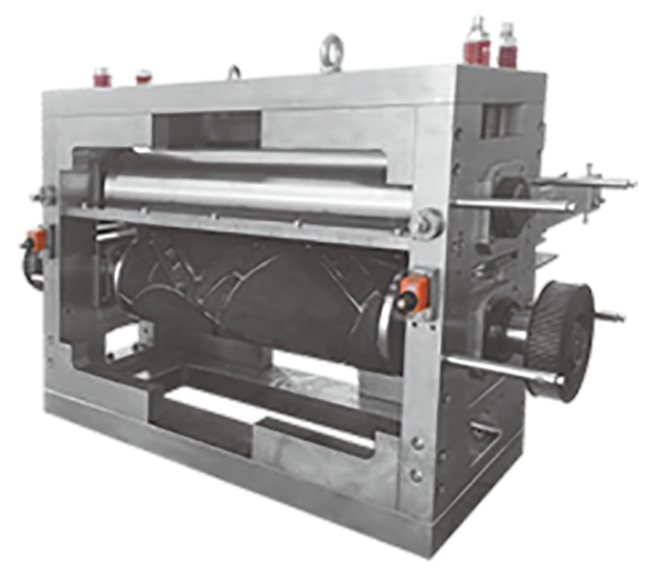

To put it simply, Embossing/Crimping Assemblies are essential tools used in manufacturing processes to create textures and secure connections. Think of them as the unsung heroes of product design. From intricate patterns on packaging to robust connections in electrical components, these assemblies serve multiple purposes.

The Rise of Automation

In today’s fast-paced world, automation is the name of the game. Businesses are constantly on the lookout for ways to streamline their processes, and guess what? Embossing/Crimping Assemblies are getting a technological makeover! With advancements in robotics, manufacturers can now produce intricate designs and connections at lightning speed.

Just imagine, instead of painstakingly creating each assembly by hand, machines can now replicate perfect patterns with ease. Talk about a game changer!

Sustainability Matters

As we all know, sustainability is more than just a buzzword; it’s a necessity. Consumers are increasingly demanding eco-friendly products, and the manufacturing industry is responding. Luckily, Embossing/Crimping Assemblies are not left out of this green revolution.

Manufacturers are now using recycled materials and sustainable practices to create these assemblies. So, not only do you get a high-quality product, but you can also feel good about using it. That’s a win-win, wouldn’t you say?

Innovative Applications

Now, let’s talk about the fun stuff—innovative applications! From automotive to electronics, the potential uses of Embossing/Crimping Assemblies are virtually limitless. In the automotive sector, for instance, these assemblies are vital for securing wiring harnesses and ensuring that everything runs smoothly.

On the flip side, in the consumer goods industry, they’re used for creating appealing packaging designs that grab attention on the shelves. Who doesn’t want to stand out in a crowded marketplace? It’s all about that visual impact!

Challenges on the Horizon

Of course, it’s not all sunshine and rainbows. As with any industry, the world of Embossing/Crimping Assemblies faces its own set of challenges. With rapid technological advancements, keeping up can be a daunting task for manufacturers. They need to invest in new equipment and training to ensure they remain competitive.

Moreover, there’s always the risk of quality control issues. One tiny misstep in the crimping process could lead to significant product failures. Yikes!

The Road Ahead

So, what’s next for Embossing/Crimping Assemblies? The future looks bright! With continuous advancements, we can expect to see even more innovative designs and applications. Who knows, maybe one day these assemblies will be integrated with smart technology, allowing for real-time monitoring and adjustments.

In conclusion, if you’re in the manufacturing game, keeping an eye on the trends surrounding Embossing/Crimping Assemblies is crucial. These little components might seem simple, but they’re packed with potential. So, buckle up and get ready for a thrilling ride into the future of manufacturing!

keywords

2025

06-16

Proway Core Punching Die-Cutting Assembly Achieves 900 Pieces/Minute in Customer Acceptance Test

2024

05-25

The 30th International Life Paper Annual Conference of Nanjing International Expo Center in 2023

2025

07-04

Innovations in Adult Diaper Cutting Technology: What You Need to Know

2025

06-27

Innovations in Adult Diaper Cutting Assembly: A Practical Approach

Social Media

Contact

Add: No. 6 Gaoyuan Industrial Zone, Meilie District, Sanming City, Fujian Province, China

Tel: +86 598 8365699

Email: sales@cnpnv.com / pnv@cnpnv.com

All Rights Reserved © 2024 Sanming PNV Machinery Co.,Ltd.

- Inquiry